ASTM A592 / A592M

This specification2 covers high-strength quenched and tempered low-alloy steel forged parts for pressure vessels. The maximum thickness of forgings under this specification shall be 11⁄2 in. [38 mm] for Grade A, and 4 in. [100 mm] for Grades E and F.Although no provision is made for supplementary requirements in this standard, the supplementary requirements in Specification A788/A788M may be considered by the purchaser. Welding technique is of fundamental importance and it is presupposed that welding procedures will be in accordance with approved methods for the class of material used.

Chemical Properties

| Grade | Carbon | Manganese | Phosphorus | Sulphur | Silicon | Nickel | Chromium | Molybdenum | Vanadium | Titanium | Zirconium | Copper | Boron |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade AA | 0.15–0.21 | 0.80–1.10 | 0.025 | 0.025 | 0.40–0.80 | ... | 0.50–0.80 | 0.18–0.28 | ... | ... | 0.05–0.15 | ... | 0.0025 max |

| Grade EA | 0.12–0.20 | 0.40–0.70 | 0.025 | 0.025 | 0.20–0.35 | ... | 1.40–2.00 | 0.40–0.60 | B | 0.04–0.10 | ... | 0.20–0.40 | 0.0015–0.005 |

| Grade FA | 0.10–0.20 | 0.60–1.00 | 0.025 | 0.025 | 0.15–0.35 | 0.70–1.00 | 0.40–0.65 | 0.40–0.60 | 0.03–0.08 | ... | ... | 0.15–0.50 | 0.002–0.006 |

A Similar to Specification A517/A517M Grades A, E, and F, respectively.

B May be substituted for part or all of titanium content on a one for one basis.

Mechanical Properties

| Size | Tensile strength, psi (MPa) | Yield strength (0.2 % offset), min,psi [MPa] | Elongation in 2 in. [50 mm],min, % | Reduction of area, min, % |

|---|---|---|---|---|

| Up to 2 1⁄2 in. [65 mm], incl | 115 000 to 135 000 [795 to 930] | 100 000 [690] | 18 | 45 |

| Over 2 1⁄2 in. to 4 in. [65 to 100 mm], incl | 105 000 to 135 000 [725 to 930] | 90 000 [620] | 17 | 40 |

Products

-

Forged Bars

Sizes :

Length :

Finish :

-

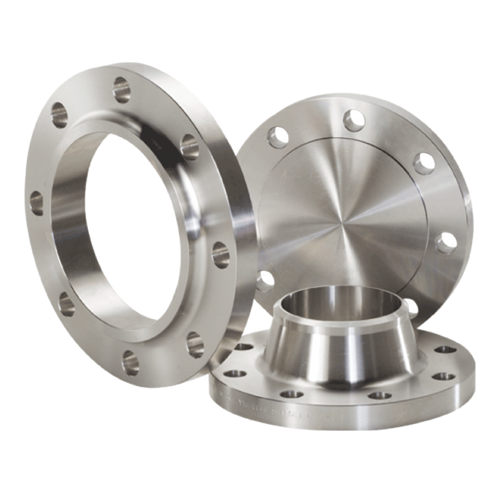

Forged Flanges

Sizes :

Length :

Finish :

-

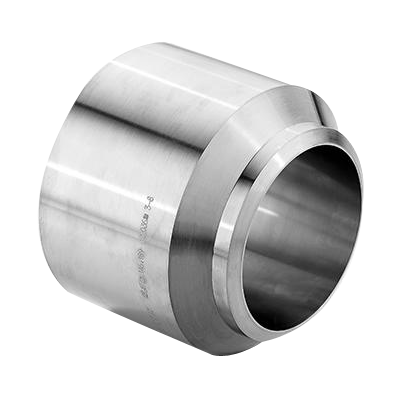

Forged Fittings

Sizes :

Length :

Finish :

-

Forged Valves

Sizes :

Length :

Finish :

-

Forged Blank

Sizes :

Length :

Finish :

-

Forged Disc

Sizes :

Length :

Finish :

-

Forged Pipe

Sizes :

Length :

Finish :

-

Forged Component

Sizes :

Length :

Finish :