ASTM A859 / A859M

This specification covers requirements for low-carbon age-hardening nickel-copper-chromium-molybdenum-columbium alloy steel forgings for pressure vessel components.Forgings under this specification are available as Grades A or B. Grade A may be ordered in one or two classes as follows:Grade A Class 1—Normalized-and-precipitation-heattreated,providing a minimum yield strength of 55 ksi [380 MPa] and a minimum tensile strength of 65 ksi [450 MPa].Grade A Class 2—Quenched-and-precipitation-heattreated,providing a minimum yield strength of 65 ksi [450 MPa] and a minimum tensile strength of 75 ksi [MPa].Grade A was the original steel composition in this specification. Although the material is readily weldable, welding procedures are of fundamental importance and must be such as not to affect adversely the properties of the material, especially in the heat-affected zone. It is presupposed that welding procedures will be suitable for the material being welded. Supplementary requirements, including those applicable in Specification A 788, are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

Grade

| Grade | Description |

|---|---|

| Grade A | - |

| Grade B | - |

Chemical Properties

| Grade | Carbon | Manganese | Phosphorus, max | Sulfur, max | Silicon, max | Chromium | Nickel | Molybdenum | Copper | Columbium | Vanadium, max | Aluminum max | Titanium max | Tin max | Arsenic max | Antimony max | Nitrogen |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade A | 0.07 max | 0.40–0.70 | 0.025 | 0.025 | 0.40 | 0.60–0.90 | 0.70–1.00 | 0.15–0.25 | 1.00–1.30 | 0.02 min | - | - | - | - | - | - | - |

| Grade B | 0.02–0.04 | 0.75–1.05 | 0.015 | 0.002 | 0.40 | 0.45–0.75 | 3.35–3.85 | 0.55–0.65 | 1.15–1.75 | 0.02–0.06 | 0.008 | 0.03 | 0.003 | 0.03 | 0.025 | 0.025 | report |

Mechanical Properties

| Grade | Yield strengthA min, ksi [MPa] | Tensile strength, min, ksi [MPa] |

Elongation in 2 in. or 50 mm, min, % |

Reduction of area, min, % | |

|---|---|---|---|---|---|

| Grade A | Class 1 | 55 [380 min] | 65–85 [450–585] | 20 | 45 |

| Class 2 | 65 [450] min | 75–95 [515–650] | 20 | 45 | |

| Grade B | 100–115 [690–800] | 105 [725] min | 16 | 45 | |

Products

-

Forged Bars

Sizes :

Length :

Finish :

-

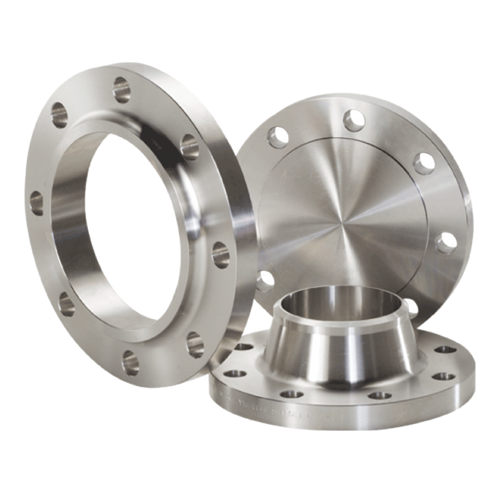

Forged Flanges

Sizes :

Length :

Finish :

-

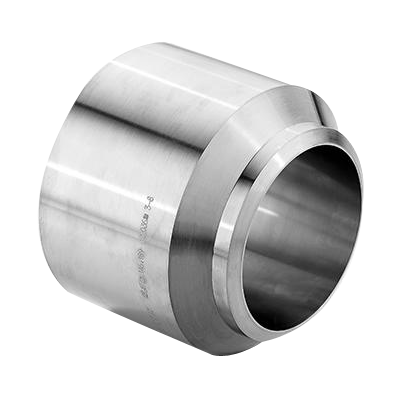

Forged Fittings

Sizes :

Length :

Finish :

-

Forged Valves

Sizes :

Length :

Finish :

-

Forged Blank

Sizes :

Length :

Finish :

-

Forged Disc

Sizes :

Length :

Finish :

-

Forged Pipe

Sizes :

Length :

Finish :

-

Forged Component

Sizes :

Length :

Finish :